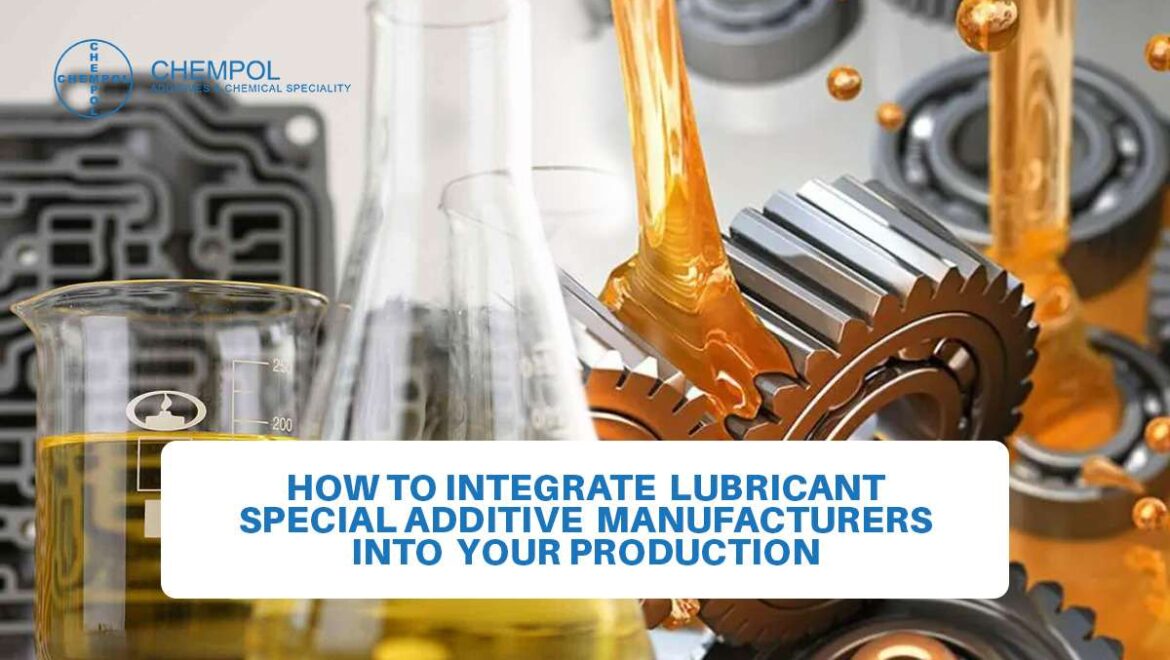

Industrial Oil Additives: Enhancing Performance and Extending Lifespan

In industrial machinery and engines, ensuring optimal performance and longevity is crucial. Industrial oil additives play a pivotal role in achieving these goals by enhancing the capabilities of lubricating oils.

The Importance of Lubrication in Industrial Machinery

Lubrication is the lifeblood of industrial machinery. It reduces friction between moving parts, dissipates heat, prevents wear and tear, and protects against corrosion. Without proper lubrication, machinery can experience premature failure and increased maintenance costs.

Comprehending Industrial Oil Additives

Industrial oil additives are meticulously formulated compounds skillfully blended into lubricating oils to reinforce their inherent characteristics. These additives are carefully engineered to harmonise with the base oil, imparting diverse advantages that enhance equipment performance.

Additionally, it’s worth noting that oil additives optimise lubrication, minimise wear and tear, and protect against corrosion and extreme conditions. The deliberate fusion of these compounds with base oils creates a well-balanced synergy that bolsters industrial machinery’s efficiency, reliability, and longevity. The industries that are hit with the use of additives are the following:

- Gasoline Engines

- Marine oil

- Diesel Engines

- Automotive

Common Types of Industrial Oil Additives

Detergents and Dispersants

Detergents in oil additives help to clean and remove deposits from engine components. Dispersants, conversely, keep contaminants suspended in the oil, preventing them from forming harmful sludge and varnish.

Anti-Wear Additives

Anti-wear additives form a protective layer on metal surfaces, reducing friction and wear. They are particularly vital in high-pressure applications where metal-to-metal contact is likely.

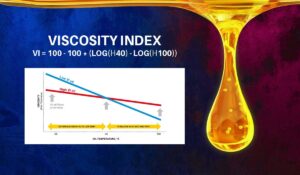

Viscosity Index Improvers

Viscosity index improvers maintain oil viscosity across a wide temperature range. They ensure consistent lubrication, regardless of whether the machinery operates in extreme cold or heat.

Anti-Foaming Agents

Foaming can reduce the effectiveness of lubrication and cause air entrainment. Anti-foaming additives prevent excessive foam formation, ensuring efficient lubrication.

Enhancing Performance with Additives

The Decline of Friction and Wear

Diesel Engine Oil Additives significantly reduce friction and wear between moving parts, minimising energy loss and extending the lifespan of the equipment.

Temperature and Oxidation Control

Additives help control oil oxidation, preventing the formation of sludge and deposits that can degrade performance. They also enhance the oil’s ability to handle high temperatures without breaking down.

Prevention of Corrosion

Corrosion inhibitors in additives create a protective barrier on metal surfaces, safeguarding against rust and corrosion, even in harsh operating conditions.

Considerations for Effective Usage

Compatibility with Base Oils

It’s crucial to ensure that the chosen additives are compatible with the base oil to achieve optimal performance without adverse reactions.

Proper Dosage

Following manufacturer recommendations for additive dosage is essential. Overdosing can lead to unintended consequences and reduced effectiveness.

Environmental Impact

Consider the environmental impact of additives, opting for eco-friendly products that comply with regulations.

Choosing the Right Additives for Your Application

Selecting the appropriate additives depends on the equipment type, operating conditions, and the desired performance improvements. Consulting with experts can help in making informed decisions.

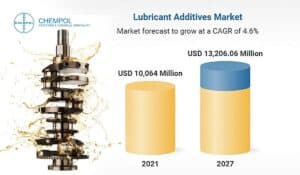

Real-World Benefits of Industrial Oil Additives

Several industries have experienced remarkable efficiency and cost savings improvements due to the strategic use of oil additives. Different studies demonstrate how customised additive solutions have extended equipment life and reduced downtime.

Is it Feasible to Introduce Additives to Depleted Oil? If So, How and What Types of Additives?

Incorporating additives into oil that has been depleted is a question that often arises in lubrication. While the replenishment of additives after depletion can be theoretically possible, it’s a practice that requires careful consideration and expertise.

Here’s a closer look at the concept and its feasibility:

Additives in Lubricants:

Most lubricants are formulated with additives, each serving specific functions tailored to their intended applications. These compounds augment the base stock properties, elevating overall performance.

Designed To Be Used Additives:

Many additives are designed to be used, meaning they are consumed or depleted over time during work.

Consequently, their concentration and efficacy diminish. This aspect is often overlooked due to scheduled oil changes or oil contamination.

Challenges and Considerations:

Reviving depleted additives is complex and only sometimes practical. Factors such as the type of additive, Viscosity Index Improver, its compatibility with the depleted oil, and the potential of adverse interactions must be evaluated.

Types of Depleted Additives:

Additives that could be depleted during a lubricant’s lifespan encompass antioxidants, rust protectants, anti-wear, extreme pressure, and anti-foam additives.

Additive Replenishment Illustration:

Consider a scenario where an antioxidant additive is introduced into in-service oil before its complete depletion. This can extend the oil’s performance, but proper understanding and consultation are crucial.

Seeking Professional Advice:

For those pondering the addition of additives to depleted oil, consulting experts in lubrication and additives is advised. They can provide insights into compatibility, optimal formulations, and potential risks.

Companies Offering Additive Replenishment:

While certain companies might offer additive replenishment services, their availability and feasibility can vary. Exploring partnerships with established experts in lubrication and additives is recommended.

While reintroducing additives to depleted oil is intriguing, it’s a practice that demands expertise and careful consideration. Collaborating with professionals in the field can provide valuable guidance on its feasibility and best practices.

Maximising the performance and longevity of your industrial machinery necessitates the astute integration of suitable industrial oil additives. These additives, by enhancing lubricating oils, exert a significant influence in curtailing wear, minimising downtime, and ensuring streamlined operation. Remember to opt for additives aligning with your equipment’s requisites, observe usage guidelines diligently, and champion environmentally responsible alternatives.

Replenishing Additives for Oil and Machinery: A Feasible Approach

Replenishing additives before oil or machinery damage occurs is viable, and many companies provide this service. You can explore these services by searching online keywords like “readditizing lubricants” or “never change your oil.” However, weighing the pros and cons of this practice is essential.

Pros:

- Cost Savings: Avoiding a complete lubricant change translates to savings regarding new lubricant procurement.

- Minimal Downtime: Depending on the service, it might not be necessary to halt the machinery for a complete changeout. Incremental additivities can occur while the equipment remains operational.

- Suitability for High-Intensity Machinery: Particularly suitable for sizable machinery with substantial lubricant volumes, running non-stop 24/7.

Cons:

- Thorough Analysis: Extensive oil analysis of the in-service lubricant becomes crucial to ascertain additive properties precisely.

- Compatibility Testing: It’s recommended to conduct compatibility tests on both the lubricant and the additives.

- Comprehensive Monitoring: Implementing a robust oil analysis program becomes imperative to track the performance of the new additive formula.

It’s essential to conduct a comprehensive cost-benefit assessment when contemplating the addition of additives to your oil. This evaluation should encompass financial expenditures, resource allocation for implementation and maintenance, and the potential extension of the lubricant’s lifespan. Your decision-making process should also consider the overarching benefits of prolonging lubricant longevity.

The decision to introduce additives to your oil is multifaceted and should be determined on a case-by-case basis. The interplay of pros and cons and your unique circumstances will guide the most suitable choice for your machinery and lubrication needs.